summary

Gas phase polymerization

The monomers are polymerized in the form of evaporated monomer, fluid catalyst and polymer particles in a fluidized bed reactor.

- Polymerization occurs at the interface between the fluidized catalyst and the polymer particles swelled with the monomer.

- The fluidized bed polymerization requires no diluent (liquid) and no residual catalyst in the resin granules or powder that is continuously discharged from the reactor.

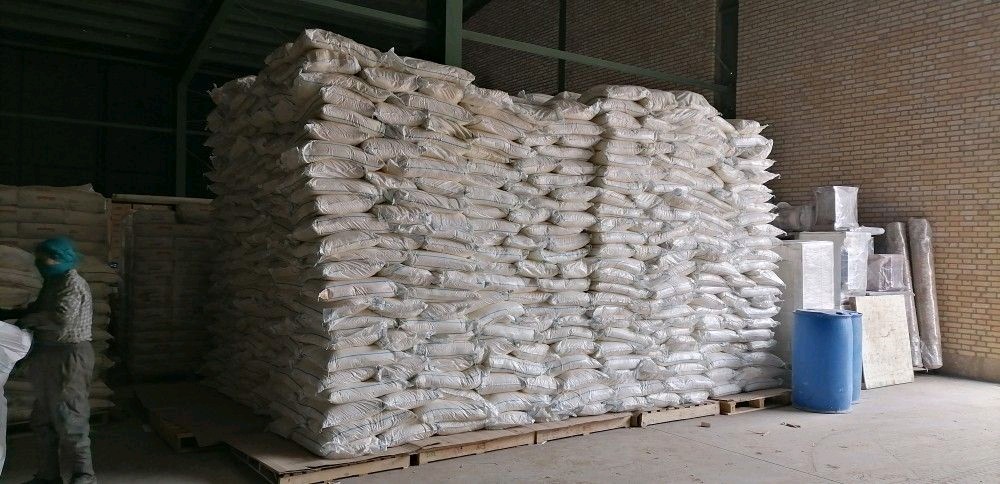

Pak Products Persian Polyaluminium Chloride (PAC)

Vapor phase polymerization, also called gas or gas fluid bed polymerization, is a widespread polymerization technique for gaseous monomers such as ethylene (LDPE, HDPE), tetrafluoroethylene (PTFE), and vinyl chloride (PVC). Many other common thermoplastic polymers can be made in this way.

This includes bulk resins such as propylene (PP), methyl methacrylate (PMMA), methyl acrylate (PMA), vinyl acetate (PVA), ethylene vinyl acetate (PEVA) and many other stable polymers in the gas phase. However, on an industrial scale, vapor phase polymerization is mainly used to produce HDPE, LDPE, and PEVA.

Fluidized bed polymerization was invented in the 1950s, and the first commercial gas phase polymerization plant using a fluidized bed reactor was built by Union Carbide in 1968. The advantage of this method is that it requires neither diluent nor residual catalyst. It does not remain in the resin or powder granules that are continually removed from the reactor. A simple flwo diagram of the process is shown in the figure below. High purity (olefinic) monomer gas is continuously fed into a fluidized bed reactor and mixed with a dry powder catalyst.

Polymerization occurs at the interface between the fluid catalyst and the polymer molecules that swell with the monomer during polymerization.

The growing and removed polymer particles sink continuously to the bottom of the reactor and are separated from the remaining monomer and prepolymer, which are returned to the reactor. The monomer (mixed with the gaseous diluent) also enters the reactor continuously and passes upward into the reactor through a series of vertical fluidized bed reaction zones. At the top of the reactor, the gas is removed, compressed, cooled, and returned to the reactor for temperature control.

The usual gas phase polymerization of olefins takes place at a temperature of 80 to 100 °C and a reactor pressure of 30 to 35 bar. The density of polyolefin is between 0.91 and 0.97 g/cm3. Common catalysts used in the polymerization of ethylene are Ziegler-Natta, coordination metallocene, Phillips 2, and transition metal catalysts.

NB

- The first commercial fluidized bed reactor was built by Standard Oil (now ExxonMobil) in Baton Rouge in 1942, and was used to crack heavy gas oil to meet the growing demand for higher-octane gasoline. construction complete

- The most widely used Phillips catalyst is chromium oxide supported on silica/alumina.