Polyaluminum chloride (PAC) has numerous applications in the steel industry. Some of its most important applications include:

- Water purification : PAC is used as an effective coagulant in water purification. It helps to separate suspended particles and colloids and makes the water clearer.

- Turbidity reduction : In steel production processes, PAC helps reduce the turbidity of water and industrial wastewater and improves the quality of water used in production processes.

- Removal of heavy metals : PAC can help remove heavy metals and organic matter from water, which is very effective in improving the quality of water used in the steel industry.

Introduction

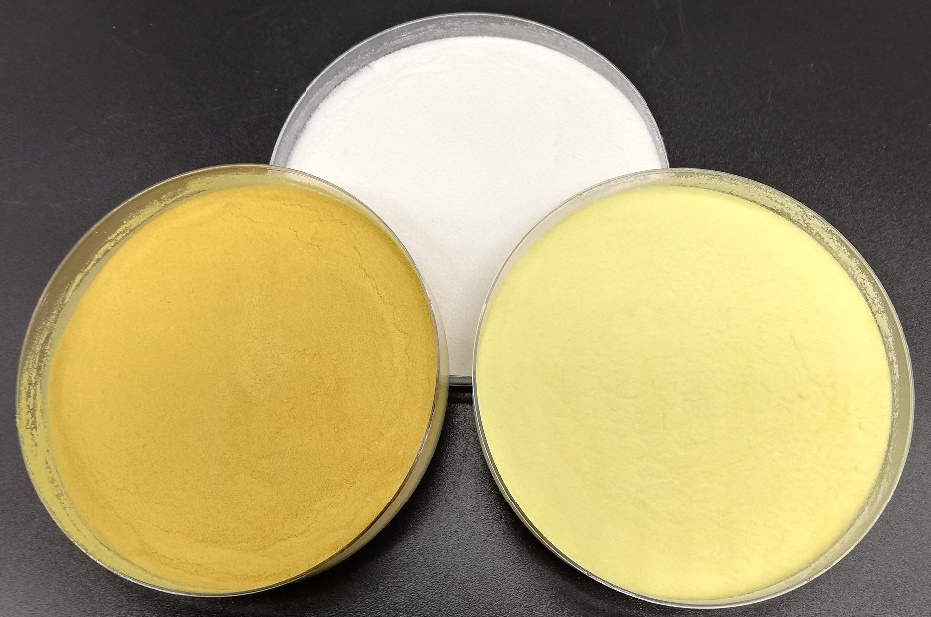

Poly Aluminum Chloride (PAC) is a versatile chemical used as a coagulant in water and wastewater treatment. Due to its unique properties, it is used in various industries, including the steel industry. In this article, we will examine the applications of poly aluminum chloride in the steel industry, its properties, processes, and importance.

Properties of Polyaluminum Chloride (PAC)

1. High coagulation power

Polyaluminum chloride has a very high coagulation power, which allows it to bind suspended particles and organic matter together and separate them from water in the form of larger flocs.

2. High solubility in water

PAC dissolves quickly in water and acts as a clear solution. This property helps increase efficiency in water and wastewater treatment processes.

3. Reducing sludge volume

The use of polyaluminum chloride helps reduce the volume of sludge produced in water treatment processes. This helps reduce sludge disposal and management costs.

4. Environmental compatibility

PAC is highly environmentally friendly and easily decomposes after use. This feature helps reduce environmental pollution.

5. High chemical stability

Polyaluminum chloride has high chemical stability and can perform well in a variety of chemical conditions. This feature helps to extend the useful life of equipment and reduce the need for repairs.

Applications of polyaluminum chloride in the steel industry

1. Raw water treatment

One of the most important applications of polyaluminum chloride in the steel industry is the treatment of raw water used in steelmaking processes. Raw water usually contains various suspended particles and organic matter that can harm the quality of steelmaking processes. The use of PAC helps to remove these particles and improve the quality of raw water.

2. Industrial water treatment

In steel production processes, a lot of industrial water is used, which may contain chemical contaminants and suspended solids. The use of polyaluminum chloride in industrial water treatment helps to remove contaminants and improve water quality.

3. Wastewater treatment

Wastewater produced in the steel industry usually contains chemical contaminants, suspended solids, and heavy metals. The use of PAC in wastewater treatment helps to remove these contaminants and reduce the pollutant load. This process helps to reduce environmental pollution and preserve the environment.

4. Improve product quality

The use of polyaluminum chloride in water and wastewater treatment helps improve the quality of steel products. High-quality water free from contaminants helps improve the final quality of steel products.

5. Increasing economic productivity

The use of PAC in water and wastewater treatment processes helps reduce production costs and increase economic efficiency. This material helps improve the efficiency of production processes and reduce maintenance and repair costs.

Processes for using polyaluminum chloride in the steel industry

1. Preparation of PAC solution

In the first step, polyaluminum chloride is prepared as a solution in water. This solution is usually prepared as a 10 to 15 percent solution. The preparation of the PAC solution must be done carefully and according to the specified instructions.

2. PAC injection into water

After preparing the PAC solution, it is injected into raw water, industrial water, or wastewater. The amount of PAC injected into the water depends on the concentration of contaminants and the process requirements.

3. Coagulation and flocculation

After PAC is injected into the water, the coagulation and flocculation process begins. In this stage, suspended particles and organic matter bind together and form larger flocs that are easily separated from the water.

4. Clot separation

The flocs formed during the coagulation and flocculation stages are separated from the water by mechanical processes such as sedimentation, filtration, or centrifugation. This process helps remove suspended particles and contaminants from the water.

5. Final purification

After floc separation, the treated water may require final treatment processes such as disinfection and pH adjustment. These processes help improve the final quality of the treated water.

Advantages of using polyaluminum chloride in the steel industry

1. Improving water and wastewater quality

The use of PAC helps improve the quality of water and wastewater used in the steel industry. It helps remove suspended particles, organic matter, and heavy metals from water, improving the final quality of water and wastewater.

2. Reducing production costs

The use of polyaluminum chloride helps reduce production costs in the steel industry. This material helps improve the efficiency of production processes and reduce maintenance and repair costs.

3. Increasing economic productivity

The use of PAC helps increase the economic productivity of the steel industry. This material helps improve the efficiency of production processes, reduce production costs, and increase yield.

4. Reducing environmental pollution

The use of polyaluminum chloride helps reduce environmental pollution from industrial wastewater. This material helps remove contaminants and reduce pollutant loads, preventing environmental pollution.

5. Increase the durability and lifespan of equipment

The use of PAC helps increase the durability and lifespan of industrial equipment. This material helps reduce corrosion and rusting of equipment, reducing the need for repairs and replacement of equipment.

Conclusion

Polyaluminum chloride (PAC) is one of the most important and widely used chemicals in the steel industry, which helps to improve the quality of water and wastewater, reduce production costs, increase economic efficiency and reduce environmental pollution. It is used in the treatment of raw water, industrial water, wastewater and to improve the quality of steel products . The use of PAC helps to improve the efficiency of production processes and increase the quality of steel products. By selecting and using polyaluminum chloride correctly, it can help to improve the quality of life and protect the environment.