introduction

Flocculation is one of the main processes in the paint industry, which is used to remove suspended particles and improve the quality of paint products. Due to its high efficiency and precision, this process is used in many stages of dye production and purification. In this article, we will look at the principles, processes and applications of sintering in the paint industry.

Principles of flocculation

Definition of coagulation

Flocculation is a process where small suspended particles are bound together using chemicals to form larger flocs. Due to their larger size, these clumps can be easily separated from the target medium.

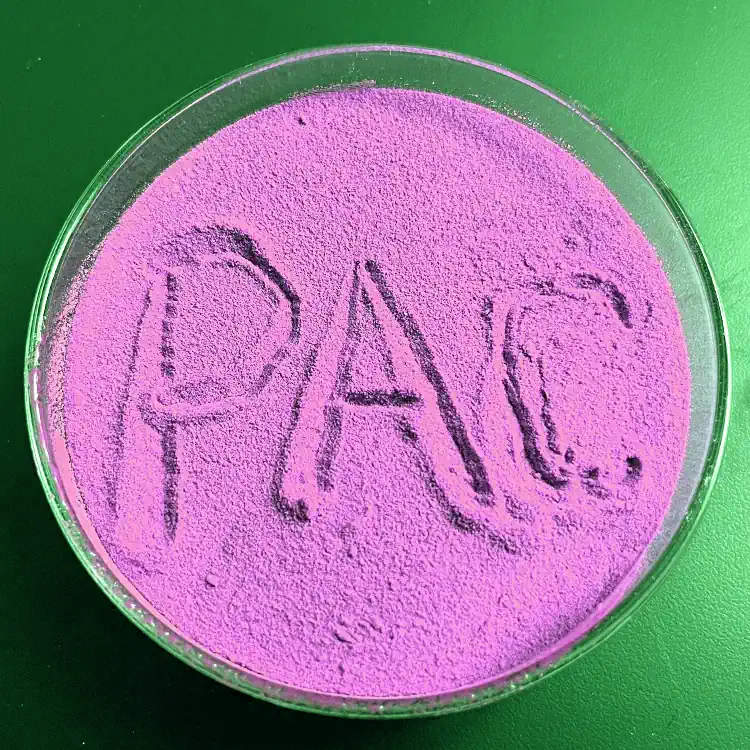

Coagulation

Flocculants are usually chemical compounds that have a specific electrical charge. These materials can bind to suspended particles and bind them together. Some common flocculants include polyacrylamide, aluminum sulfate, and ferric chloride.

Mechanism of coagulation

The sintering process usually occurs in two stages:

- Coagulation : In this stage, suspended particles are bound together with the help of coagulants and form smaller clumps.

- Flocculation : During this stage, small clumps are converted into larger clumps that can be easily separated from the desired medium.

Flocculation processes in the paint and varnish industry

1. Preparation of raw materials

In the early stages of paint production, raw materials must be well prepared. These materials typically include dyes, resins, and solvents. At this stage, the use of flocculation helps separate suspended particles and impurities and improve the quality of the raw materials.

2. Color production

At the stage of color production, sintering is used as one of the main stages. At this stage, coloring compounds and additives are thoroughly mixed and unwanted clots are separated from the environment. This process helps to improve color uniformity and improve the quality of the final product.

3. Industrial water purification

Many industrial waters are used in paint manufacturing processes. This water may contain suspended particles and various contaminants. Using the flocculation process in industrial water treatment helps remove these contaminants and improve water quality.

4. Recycling and waste management

In the coatings industry, proper waste disposal and recycling of materials is very important. Using the flocculation process in waste disposal helps to separate and recycle useful materials and prevents environmental pollution.

Application of flocculation in the paint and varnish industry

1. Improve color rendering quality.

One of the most important applications of flocculation in the paint industry is to improve the quality of paints. This process helps remove suspended particles and impurities from paint formulations, and improves color consistency and uniformity.

2. Increased color stability.

The use of a sintering process in the production of colors helps to increase the stability and durability of the color. This process helps to reduce the impact of harmful substances and impurities on colors and increases the service life of colored products.

3. Improvement of production processes

Flocculation helps improve paint manufacturing processes and increase their efficiency. This process helps reduce production costs, increase productivity and improve product quality.

4. Reducing environmental pollution

The use of flocculation process in waste disposal and industrial water treatment helps to reduce environmental pollution. This process helps to separate and remove harmful substances from industrial waste and water, and prevents environmental pollution.

5. Increasing economic productivity

The use of sintering process helps to improve the economic productivity of coating companies. This process helps to reduce production costs, improve efficiency and economic productivity, and increase the profitability of the coatings industry.

Advantages of using flocculation in the paint industry

1. Improve product quality

The use of the sintering process helps to improve the quality of colored products. This process helps to remove impurities and suspended particles from the coloring compositions, and also improves the consistency and uniformity of the color.

2. Reduction of production costs

The use of sintering process helps to reduce production costs in the paint industry. This process helps to increase the efficiency and productivity of production processes and reduce operating costs.

3. Increased durability and stability of products.

The use of sintering process helps to increase the durability and stability of color products. This process helps to reduce the impact of harmful substances and impurities on colors and increases the service life of the products.

4. Environmental protection

Using the flocculation process helps to protect the environment. This process helps to reduce environmental pollution and prevent environmental degradation.

5. Increasing economic productivity

The use of sintering process helps to improve the economic productivity of coating companies. This process helps to reduce production costs, improve efficiency and economic productivity, and increase the profitability of the coatings industry.

Problems and limitations of using flocculation in the paint and varnish industry

1. Cost of coagulants

One of the problems with the flocculation process is the cost of flocculants. Using quality and appropriate materials requires investment, which can increase production costs.

2. Need for experience and technical knowledge

The use of the sintering process requires experience and technical knowledge. Paint and varnish production workers and managers must be familiar with the principles and mechanisms of sintering in order to use the process optimally.

3. Strict process control

The flocculation process requires careful monitoring and proper management. Any error in the settings and management of the process can lead to a decrease in the efficiency and quality of the product.

conclusion

Sintering is one of the main processes in the paint industry, which helps remove suspended particles, improve product quality, enhance color fastness, and reduce environmental pollution. This process is used in various stages of paint production and cleaning, and helps improve the efficiency and productivity of the paint industry. However, the use of flocculation requires careful management, technical knowledge, and appropriate control to achieve optimal performance. By choosing and applying the flocculation process correctly, you can improve the quality of life and save the environment.