SAN is a copolymer of styrene and acrylonitrile belonging to the family of plastics, more specifically, to styrene polymers (of which the best known is polystyrene).

Globally, SAN production represents only 1% of the styrene market, led by polystyrene (50%), SBR rubber (15%) and ABS (11%).

European SAN production (67,000 t) is shared between Basf, Dow, Enichem, Monsanto and Repsol, which sells mainly in Spain. Since 1992, capacities of 22,000 t have been closed in Europe and new facilities have been started up, producing 45,000 t/year, although these are also dedicated to obtaining ABS.

Since primary consumers of SAN products are highly dependent on general economic conditions and no new applications or substitutions are anticipated, SAN is projected to grow at an annual rate of approximately 2%.

SAN can be found in a wide range of applications, whether in the technical sector (manufacturing of household items), the medical sector (disposable dialysis equipment) or the food industry (due to its qualities it represents an excellent barrier against humidity and CO2 , and is used as a food protector).

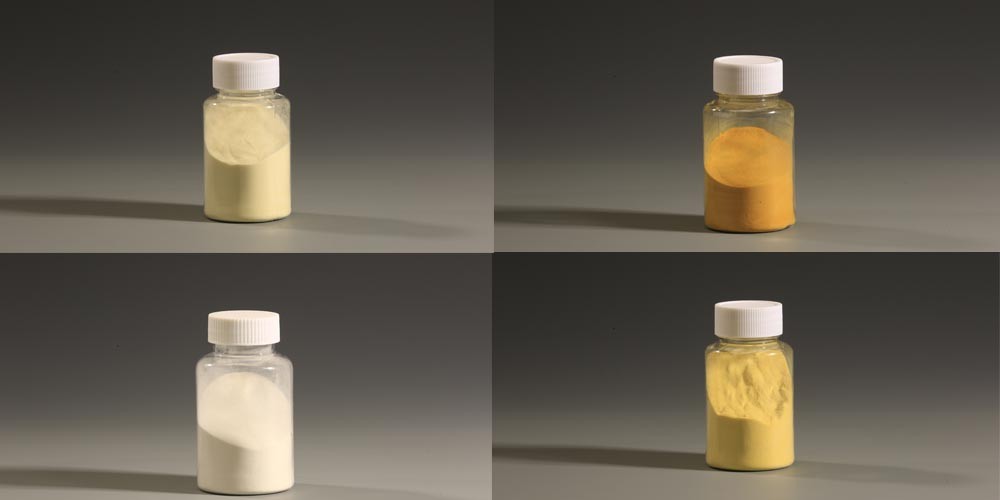

Presentation of SAN

A “copolymer” is a polymer formed by two different structural units (monomers): in this case, styrene and acrylonitrile. The most common composition of SAN is 65 to 80% styrene, and the rest acrylonitrile, depending on these proportions the final characteristics of the product. Its chemical structure is shown below:

The main producers of SAN worldwide and their commercial names are:

- MONSANTO: “THEY POLISH”.

- BASF: “LURAN”.

- DOW: “TYRIL”.

- BAYER: “NOVODUR W”.

SAN Features

Considering the combined characteristics of styrene and acrylonitrile, the main characteristics of SAN are:

Group: Thermoplastic.

Optical properties: Crystalline.

Mechanical properties at room temperature:

- Flexible

- Rigid

- Plastically deformable

- Hard

- Fragile

- It is transparent, amorphous in structure and easily processed. Any type of mechanical treatment can be used for its manufacture.

- It has better impact, tension and flexural properties than styrene homopolymers (characteristics provided by acrylonitrile).

- It is resistant to oils, greases, formaldehyde, gasoline and hydrochloric acid.

- It is not chemically attacked by water.

- It has great surface shine.

- It has very low water absorption.

- Low manufacturing cost and easy process.

- High stiffness.

- Very good thermal resistance.

- Density: 1.08 gr/cm3.

Combustion test

Behavior: Produces a lot of ash flakes

Flame appearance: Bright yellow, flickers

Flame behavior: Yellow

Odor and reaction of vapors: Odor of styrene and HCl (Hydrochloric acid).