Polyaluminium chloride (PAC) has many applications in the petroleum and petrochemical industries. It is used as a coagulant and flocculant in water and wastewater treatment processes. Some of the main applications of PAC in these industries are:

- Water and Wastewater Treatment : PAC is used as an effective aid in water and wastewater treatment due to its flocculation and sedimentation properties.

- Odor Control : PAC is used as a highly effective compound to reduce odors arising from waste and wastewater treatment processes.

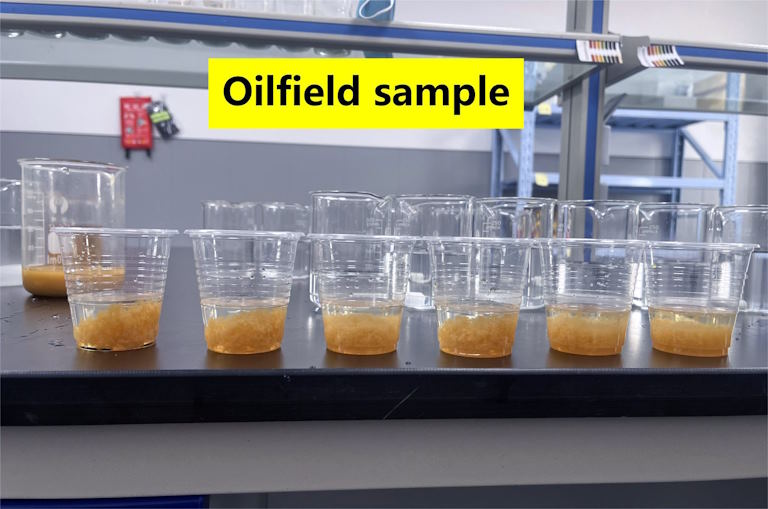

- Industrial Wastewater Treatment : In the petroleum and petrochemical industries, PAC is used to remove turbidity and suspended solids in wastewater.

Polyaluminum chloride (PAC) is one of the most widely used chemical compounds in the petroleum and petrochemical industries. This substance is used as a strong coagulant in various water and industrial wastewater treatment processes, as well as in chemical processes related to the production of petroleum and petrochemical products. Below, we will discuss the applications of polyaluminum chloride in the petroleum and petrochemical industries and the benefits of its use.

What is polyaluminium chloride?

Polyaluminium chloride (PAC) is an inorganic chemical compound produced by the reaction of aluminium with chloride. This substance is available in solid and liquid form and is known as an effective agent in water and industrial wastewater treatment due to its strong coagulant properties. PAC has become one of the main options in various industries due to its high efficiency and low dosage compared to other coagulants.

Application of PAC in the petroleum and petrochemical industries

1. Water purification

In the petroleum and petrochemical industries, the use of clean and purified water is critical for various processes. Due to its coagulation properties, PAC can help remove suspended solids, microbial contamination and other contaminants from water, as well as improve the quality of drinking water. This helps improve production processes and increase productivity.

2. Industrial wastewater treatment

Industrial wastewater generated from petroleum and petrochemical production processes usually contains various pollutants that need to be treated. PAC, with its coagulation ability, can help remove pollutants from industrial wastewater and bring it to a level suitable for discharge into the environment. This helps reduce environmental pollution and protect natural resources.

3. Improving the quality of water injected into oil wells.

During the oil production process, water is injected into oil wells to increase pressure and facilitate the extraction of oil from reservoirs. By improving the quality of the injected water, PAC can help improve the efficiency of this process and reduce problems associated with microbial and chemical contamination.

4. Improving recycling processes

In oil and gas refineries, the use of clean and purified water is essential for various refining and petrochemical production processes. By improving the quality of the water used, PAC can help improve the efficiency of cleaning processes and reduce problems associated with microbial and chemical contamination.

5. Removal of pollutants in petrochemical production processes.

In petrochemical manufacturing processes, the presence of contaminants can compromise the final product quality. With its coagulating properties, PAC can help remove these contaminants from chemical solutions and improve the final product quality.

6. Reduce the use of chemicals

The use of PACs in water and industrial wastewater treatment processes can help reduce the consumption of other chemicals. This helps reduce production costs and protect the environment. Due to the high efficiency of contaminant removal and the reduction of water turbidity, PACs can reduce the need for other chemicals.

Benefits of using PAHs in the oil and petrochemical industries

1. High efficiency

Due to its high efficiency in removing contaminants and suspended solids, PAC can help improve the quality of drinking water and industrial wastewater, and requires a lower dosage than other coagulants.

2. Improve the quality of the final product.

Using clean, purified water in petroleum and petrochemical production processes can help improve final product quality and reduce problems associated with microbial and chemical contamination.

3. Cost reduction

Due to the high efficiency of PAC and the lower dosage required, the use of this material can help reduce water and wastewater treatment costs and improve productivity.

4. Environmental protection

By using PAC, industrial wastewater can be effectively treated and avoid pollution of water sources and the environment. This helps to conserve natural resources and reduce the negative impact on the environment.

5. Economical and affordable.

The use of PAHs in water and wastewater treatment processes can help reduce production costs and improve productivity. This substance has become one of the main options in the oil and petrochemical industries due to the need for lower dosage and high efficiency.

6. Reduce consumption of other chemicals

The use of PAHs can help reduce the consumption of other chemicals in oil and petrochemical production processes. This helps reduce costs and protect the environment.

conclusion

Aluminum chloride (PAC) is one of the most important bio-based materials in the petroleum and petrochemical industry due to its strong coagulant properties and diverse applications. From water and industrial wastewater treatment to optimizing refining and petrochemical production processes, PAC plays a very important role in optimizing production processes and ensuring the quality of final products. This material has become one of the main choices in this industry due to its high efficiency and many benefits.

By reducing costs, increasing productivity and improving the quality of end products, PAC has become one of the key success factors in the oil and petrochemical industries. Due to the numerous benefits of this material, the use of PAC in oil and petrochemical production processes can help improve productivity and reduce environmental impact.